The partner is a trader, and the molds need to be exported. This product is a building environmental protection project, with new building structures and new building environmental protection materials. The main technical difficulties are as follows:

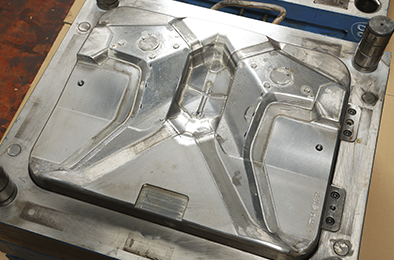

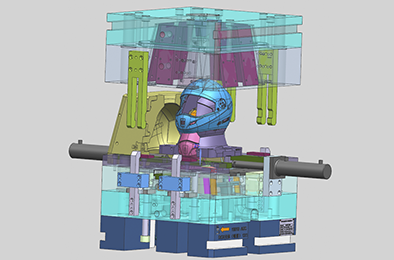

Mold: This product is spliced with each other. It is required that there should be no mold inclination around the product, and full-automatic injection molding should also be realized. The product belongs to deep cavity, which is difficult to process, and the inner shape is complex. Moreover, there must be a cooling system in each mold part. We split the mold core into more than 100 parts, all of which are precision machined by high-speed machine. The inner deep cavity is processed by precision spark machining, and then all parts are spliced without grinding, so that the mold can be produced smoothly, and the production rhythm is within the scope of customer understanding.

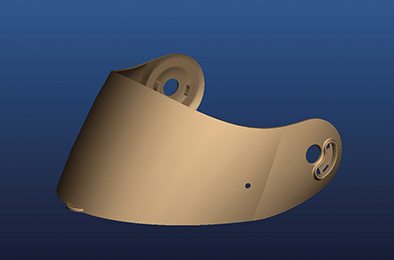

Injection molding product processing: as this is a new type of plastic, containing wood powder, poor fluidity and relatively complex product structure, temperature control is also particularly important. The control of injection molding temperature plays a key role in the appearance of this product.

It took half a year before and after the project, which was successfully exported and received satisfactory feedback from end customers. Every new material project needs to be professional and patient enough to help customers create successful products.